1220*2440mm 12mm 14mm 16mm 18mm 20mm Selected Walnut Finger Jointed Board Glued Wood Panels Euro Spruce Board

Basic Info.

| Model NO. | CFPC-PANELS |

| Timber Type | Radiata Pine |

| Usage | Indoor, Outdoor |

| Burl | Without Burl |

| Finger Joint Position | on Face or on Lateral |

| Micro Finger Joint | Finger Blade Size 4mm |

| Lead Time | 2-3 Weeks |

| Moisture | 8+/-2% |

| Width/Length Tolerance | <0.2mm |

| Application | High End Furniture,Coffin,Surfboard,Interior |

| Thickness Tolerance | <0.1mm |

| Surface Treatment | Non Finished,Single ,Semi-Glossy,Highlights,White |

| Species | Radiata Pine.Beech Natural,Oak,Maple,Ash,Cherry |

| Grade | A/A Grade,a/B Grade,B/B,B/C Grade |

| Glue | D3.D4 |

| Types | Finger Joint Panels,Egp Without Fj |

| Core | Radiata Pine,Spruce,Poplar |

| Finger Joint | Top Finger ( Micro Finger Finger - Finger Blade 4m |

| Sanding | 150 or 180 Grit Sanding |

| Transport Package | by Pallets |

| Specification | 1220*2440mm, customized |

| Trademark | cfpcsd |

| Origin | China |

| HS Code | 4407999019 |

| Production Capacity | 5000cbm/Month |

Product Description

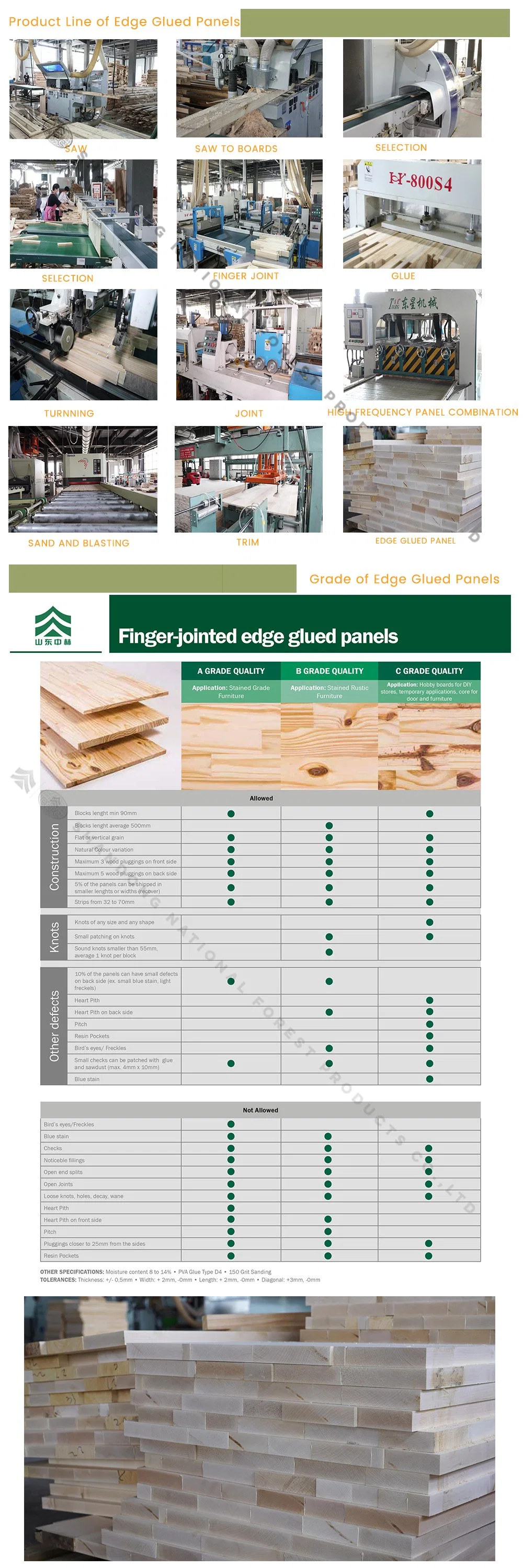

>>Edge Glued Panel Description

Species:-Radiata pine- Beech natural (not steamed)- Beech (steamed)- Beech red heart (rustic)- European Oak- European Maple- Ash tree- Cherry natural or steamed- Black locust (acacia) steamed- WhitebeamTypes and dimensions- Finger jointed panels (from finger-jointed hardwood staves, same lamella's width on a board)- Solid wood panels (made from strips, approx. random width 40-100mm)Finger jointed panels:- Thickness: 18/19/20, 26/27, 38/40, 43 mm or customized- Lengths: up to 4600mm- Widths: up to 1300 mmGlued panels with solid staves:- Thickness: 18/19/20, 26/27, 38/40, 45mm or customized- Lengths: Furniture boards up to 2500mm, stair treads and raisers 900-1800mm- Widths: up to 1300mmGradingA/B grade - Furniture grade- Side A (face side): clean, no red heart (beech wood), free of knots, and discolorations, consistent structure, and color, oak without sapwood- Side B (bottom side): no red heart, free of knots, natural stains, oak with some sapwood.B/B grade- Side A: small strips of red heart allowed (beech wood), free of knots, natural discolorations, sapwood strips allowed for oak- Side B (bottom side): red heart allowed, small pin knots, natural stains, sapwood allowed for oak, putting allowed.B/C grade- Side A: small strips of red heart allowed (beech wood), free of knots, natural discolorations, sapwood allowed for oak- Side B (bottom side): red heart allowed, small knots, natural stains, sapwood allowed for oak, putting allowedC/C grade (red heart panels)- Side A: beech naturally colored, sound red heart decoratively wanted, discolorations allowed, knots and mineral strike.- Side B (bottom side): beech naturally colored, sound red heart decoratively wanted, discolorations allowed, knots and mineral strikes, putting allowed.

Edge glued lumber panels are an important component of many high quality furniture designs.Edged glued panels may be used for exposed furniture parts (such as doors), face glued intonsquares for turning or used as core material for hardwood plywood. In any case,it is imperativenthat the panels be manufactured with strong glue bonds, closed joints, smooth surfaces, and be free of cup and warp.

Product Name | Solid Wood Edge Glued Board |

Model Number | CFPC-EGP-001 |

Material | pine |

Mainly Material | paulownia, fir, pine, poplar, birch, spruce |

Color | Natural Wooden Color or Bleached |

Grade | AA, AB, BB, BC |

Density | 300-350KGS/CBM |

Moisture Content | 6%-12% |

Thickness | 3-55mm |

Size | 1220*2440 or as customized |

Delivery time | shipped in 15-25 days after payment |

Payment term | TT/LC |

Certificate | ISO9001, FSC, BV |

Feature | stable and solid , natural twxture , green and evirmment protection, excellent hygrosscopicity adn are permeability |

Packing details | 1) Inner Packing:Pallet is wrapped with a 0.2 plastic paper. |

>>Edge Glued Panel Quality Control

To insure panels of consistent good quality, it is important that the manufacturer carefully monitor several crucial aspects of the edge gluing process. When edge gluing difficult species, it is especially crucial that manufacturersfollow strict quality control practices. The purpose of this report is to discuss proper manufacturing techniquesnecessary for quality panels.Proper manufacturing techniques are essential for quality edge glued panels. To insure proper techniques are followed, a structured quality control program must be in place,the most important manufacturing concerns related to achieving quality panels and offers suggestions for designing a quality control program. The manufacturer must take this information and design a program which best fits their process needs and concerns. Equally important is that the manufacturer monitor and maintain their manufacturing equipment. Broken clamps, worn bearings, missing machine parts, and poorly adjusted machines arecommon causes of poorly manufactured panels. The cost of neglecting equipment is high. Likewise, manufacturers should seek advice from their adhesivesuppliers and equipment manufacturers. Many companies offer good technical support and educational materials as a service to customers. Much can be learned from the experiences of those who deal with similar problems on a daily basis.

1. Quality edge glued panels cannot be manufactured from improperly manufactured lumber.The lumber must be dried to a moisture content appropriate for the environment of its intended end-use (6-8% ).

2.Machining of Panel Components Panel components must be machined properly to achieve a quality panel. Machined parts must be straight,have parallel and square edges, and surfaces of good quality.

3.It is also important that the edges are machined square. When edges are not square, a gap occurs along one edge of the glue line. When this gap is on the face of the panel (in view of the operator), the operator will often apply extra pressure to force the components together.

4.It also important the surfaces to be glued are of good quality. Surfaces should be smooth with no burnishing, fuzziness, or deep tooth marks. Burnished surfaces do not allow for good glue penetration and thus weak glue bonds are formed.5.Finally, components should be glued together shortly after machining. Components in storage can get dirty and pick up moisture, both of which affect glue bond performance.

6.Gluing and Clamping Components must be properly glued to achieve a quality panel. It is important the proper glue formulation be used for the species, plant conditions, clamp cycle, and target moisture content of the components. If a new species of wood is to be glued,

OSB:

Professional log's purchase teamSustainable forest management systemEnsure stable quality and quantity supplyTrade with more than 10 countries in the worldWood application and products R&D test site ,Area more than 6.7 HectaresRigorous production processHigh Frequency panel combinationPlanning & sandingMore than 20 years experience of carpenterSelect the world's top 500 partnersEuropean waterborne paintCustomize PackageMain catagory:OSB/1 - General purpose boards and boards for interior fitments (including furniture) for use in dry conditions.

OSB/2 - Load-bearing boards for use in dry conditions.

OSB/3 - Load-bearing boards for use in humid conditions

OSB/4 - Heavy-duty load-bearing boards for use in humid conditions.

MDF:

Professional log's purchase teamSustainable forest management systemEnsure stable quality and quantity supplyTrade with more than 10 countries in the worldWood application and products R&D test site ,Area more than 6.7 HectaresRigorous production processHigh Frequency panel combinationPlanning & sandingMore than 20 years experience of carpenterSelect the world's top 500 partnersEuropean waterborne paintCustomize PackageMain catagory:Fine Surface MDFHigh Densit FiberboardMelamine Paper MDFGreen Waterproof MDFRed Fire Retardant MDF

Plywood:

Our hardwood plywood for different markets :

Super flat for making furniture, interior decoration ,high-end users,free of defects

B/BB grade plywood ,premium quality for making furniture ,interior decoration

BB/CC grade plywood ,making furniture,decoration roofing ,subfloor

B/B grade birch plywood,top quality for making high quality furniture ,mainly to USA,Europe

Bintangor Plywood

CDX grade plywood -i.e. C-D exposure

DBB/CC grade plywood

Full birch plywood

Full hardwood plywood

Packing plywood

Combi(combination)plywood/film

Pine plywood for UK,Ireland and other

UTY grade plywood

E0 grade for formaldehyede

C+/C pine plywood

Red Canarium plywood

>>Our Solid Wood Furniture

1.Free sample

2.Complete catalog

3.Marketting consult service

4.Import logs

5.Customize your project

6.Design your furniture